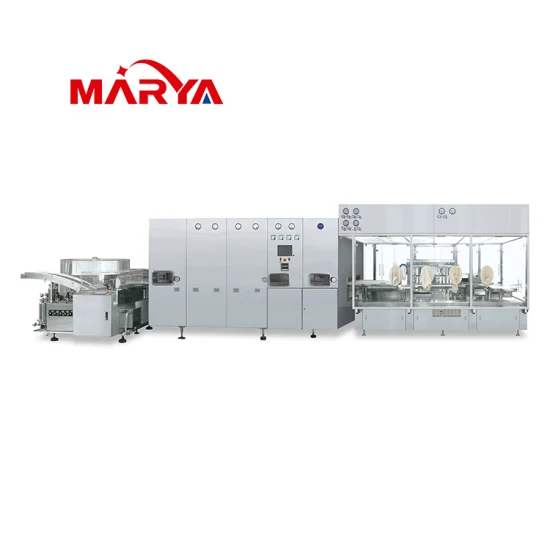

Marya Pharmaceutical Ampoule Bottle Washing Sterilizing Filling Sealing Production Line Supplier with CE ISO Certificate

Description

Basic Info.

| Model NO. | MY-AL |

| Certification | CE, GMP, ISO, SGS |

| Voltage | Customized |

| Computerized | Computerized |

| Customized | Customized |

| Condition | New |

| Warranty | 1 Year |

| After-sales Service | 1 Year Warranty |

| Certificate | CE, ISO, SGS |

| Machine Size | 3500*1500*1800mm |

| Driven Type | Electric |

| Application | Chemical, Medical, Food |

| Machine Power | 1.8 Kw |

| Machine Weight | 1200 Kg |

| Capacity | 100-600bpm |

| Filling Volume | 1-20 Ml |

| Transport Package | Inner Water Proof Bag, Outer Sea Worth Case |

| Specification | Customized |

| Trademark | Marya |

| Origin | China |

| HS Code | 8422303090 |

| Production Capacity | 30 Sets/Year |

Packaging & Delivery

Package Size 350.00cm * 150.00cm * 180.00cm Package Gross Weight 1200.000kgProduct Description

Marya Pharmaceutical Ampoule Bottle Washing Sterilizing Filling Sealing Production Line Supplier with CE ISO CertificateProduct Description

OverviewWhenever glass containers are at play, production processes become challenging. Glass ampoules are no exception: cleaning, filling, closing and inspecting the much-used containers require care and precision. At Marya, we have a passion for both: our ampoule filling and sealing machines for low to high-output production ensure gentle, hygienic and accurate processing. Different burning stations, filling technologies and handling systems allow us to tailor our systems to your production settings. Our portfolio enables us to easily combine all machines with upstream and downstream equipment , effectively supporting your entire production line.This linkage production line is composed of ultrasonic bottle washing machine, sterilization dryer and ampoule filling and sealing machine. It can complete the complex functions of spraying water, ultrasonic cleaning, bottle inner and outer wall flushing/flushing, preheating, drying and sterilization, heat removal, cooling, (pre-nitrogen filling), filling, (post-nitrogen filling), sealing, etc. The whole production process can be completed under the protection of A-level laminar flow and realize the whole process of automatic production. The parameters of the filling can be managed by the formula, and the size of the sealing flame can be adjusted by the flowmeter when sealing. The entire filling and sealing process is monitored in real time and can be traced to ensure good filling and sealing results and reliable repeatability. The functions and technical indicators of the unit can comply with our pharmacopoeia and GMP standards of the production of water injection products. Each can be used alone, but also in linkage production.

ApplicationThe ampoule filling line is mainly used for the filling of ampoule injection drugs in pharmaceutical factories, including but not limited to the filling of basic drugs and diluents such as vaccines, hormones, painkillers, anti-inflammatory drugs, emergency drugs and anesthetics. Ordinary ampoule filling machines can also be used for the filling of antibiotic ampoule injection bottles or powder filling.Performance features(1) "arc screw" in and out of the bottle, effectively reduce the risk of broken bottles (2) The lifting of the needle frame can walk the movement curve to reduce the phenomenon of splashing during the filling process (3) The filling pump can walk the movement curve to effectively reduce the occurrence of carbonization (4) Needle rack and clamp rack have high stop function (5) Synchronous with rotating bottle mechanism, rotating bottle action is independent and adjustable (6) Remote diagnosis function can be realized (7) The structure of the unit is reasonable and covers a small area.(8) The production process is carried out under sealed or laminar flow conditions to prevent cross contamination and meet GMP requirements (9) It can produce a variety of specifications of water needle preparations, has quick replacement specifications and good versatility

Advantages

1. Wide range of bottle specifications, high filling accuracy:(1)Applicable specification: 1ml-20ml ampoule (as per user's requirement)(2)Production Capacity: 12000-36000BPH(3)Number of filling head: 2-20, to be selected according to output(4)Filling Accuracy: ≤ ±1% (according to drug characteristics)(5)Choice of various filling pumps: glass pump, metal pump, peristaltic pump, ceramic pump;2. Intelligent control system, production process automation, easy operation and maintenance, less operators, high production efficiency:(1)The whole ampoule filling line meets new GMP requirements and ISO standard;(2)Adopting straight-line layout or wall-to-wall L-shaped layout to reduce risk of cross-contamination and ensure aseptic level;(3)Various sealing gas supply methods such as natural gas or hydrogen and oxygen gas;(4)The maximum sterilization temperature of hot air circulation tunnel oven is 350ºC;(5)Evenly distributed heat of the hot air circulation tunnel oven, good heat sources removal effect;(6)High degree of automation, many control technologies can be used: high precision colored touch screen operation monitoring, PLC automatic control&automatic protection, host frequency conversion speed regulation, etc.(7)Our production line has full-line linkage function, front and rear equipment linkage control.

3. Many optional functions, customize ampoule filling line according to your needs:Marya ampoule liquid filling line can provide the following optional functions:(1)Open-RABS/Close-RABS isolation protection system and class 100 laminar flow hood protection;(2)Optional CIP/SIP system;(3)Real-time display and printing system of sterilization temperature;(4)Function of High-performance no-bottle-no-filling and machine stop for bottle jam;(5)Online monitoring system to monitor key factors that affect product quality (such as dust particles, planktonic bacteria, air speed, air pressure, etc.)(6) Automatic ignition function can be configured(7) Automatic sampling function can be configuredTechnical Parameter:

| Product Model | MYA-2 | MYA-4 | MYA-6 | MYA-8 | MYA-10 | MYA-12 | MYA-16 | MYA-20 |

| Suitable size(ml) | 2-30(ampoules) | |||||||

| Output(pcs/min) | 20-60 | 40-120 | 60-200 | 100-250 | 120-300 | 150-400 | 200-500 | 280-600 |

| Filling heads | 2 | 4 | 6 | 8 | 10 | 12 | 16 | 20 |

| Power supply | 380V 50HZ | |||||||

| Power capacity(kW) | 79 | 79 | 90 | 92 | 108 | 108 | 115 | 132 |

| Total weight(kg) | 8500 | 8500 | 8800 | 9300 | 9900 | 10200 | 10800 | 11800 |

| Overall diemensions(mm) | 9050*2200*2450 | 9050*2200*2450 | 9700*2200*2450 | 9700*2200*2450 | 1080*2200*2450 | 1080*2200*2450 | 1170*2200*2450 | 1170*2200*2450 |

About Us & Why Choose Us

Workshop & Certificate

Product Category

Project case

Our Customer

Exhibition & Our Team

Packaging & Shipping

Marya SO GMP Standard Cosmetic Glass Veterinary Tube Ampoule Filling Production LinOur Contact