Marya GMP Standard Pharmaceutical GMP Standard Cleanroom HVAC System Manufacturers

Description

Basic Info.

| Usage | Warehouse, Villa, Dormitories, Temporary Offices, Workshop |

| Certification | ISO, CE, SGS |

| Customized | Customized |

| Transport Package | Standard Export Package |

| Specification | Standard/Customized |

| Trademark | Marya |

| Origin | China |

| Production Capacity | 10000PCS/Month |

Packaging & Delivery

Package Size 100.00cm * 100.00cm * 100.00cm Package Gross Weight 50.000kgProduct Description

Marya GMP Standard Pharmaceutical GMP Standard Cleanroom HVAC System Manufacturers

Product Description

Marya Advantages:

1. Our cleanroom cleanliness level is high, meeting the requirements of GMP, WHO and other pharmaceutical standard;2. Able to realize BMS automatic control;3. Modular design, fast installation;4. Construction material are CE certified;5. High degree of safety, equipped with safety doors and fire dampers;6. From A-Z, one-stop service from design to construction verification;7. Can accurately control the temperature, humidity, pressure difference, the number of dust particles and planktonic bacteria;8. The brand of HVAC can be specified by customer;9. Able to send workers abroad for installation;10. We have a strong design team, able to design according to customers' different needs.

Technical Parameters:

| Effective width | Wall panel: 950mm 1150mmCeiling panel: 950mm |

| Length | According to customer's request(less than 7500mm) |

| Core Materials | PU/Rock Wool/Glass Magnesium |

| Structure | Upper and lower layer: Color steel sheet |

| Middle: PU/Rock Wool/Glass Magnesium | |

| Thickness | Color steel sheet: 0.3-0.8mmRock wool: 50mm 75mm 100mm |

| The Density of Rock Wool | 40kg/m3 -120kg/m3 |

| Color | RAL Standard |

| Character | Fireproof, heat insulation, sound proof, green and environmental friendly |

| Use | pharmaceutical & electronic clean rooms, hospital operating rooms, food processing factories, offices, etc. |

This customer is a Bangladesh cleanroom contractor, cooperated with us for the 1st clean room project in 2019, and we have successfully completed the 2nd clean room project for them in 2020. The new clean room project for year 2021 is still in production. For these 3 projects, We have provided this customer with quick delivery time, flexible payment, and high quality products(cleanroom doors, sandwich panels, windows, weighing booth, pass box, and other materials and equipment). So our services can win great recognition from customers. Israel project

This customer is very loyal, they are a cleanroom contractor in Israel. We started to cooperate on the first clean room project in 2018 and have completed 3 clean room projects for them till 2019. We have provided customers with cleanroom doors, sandwich panels, windows, epoxy floors, air shower, pass box, and other materials and equipment and on-site installation services for all 3 projects. Customers are very satisfied with our sales service and installation service, and are impressed by the professionalism and dedication of our on-site construction staff.

About Us

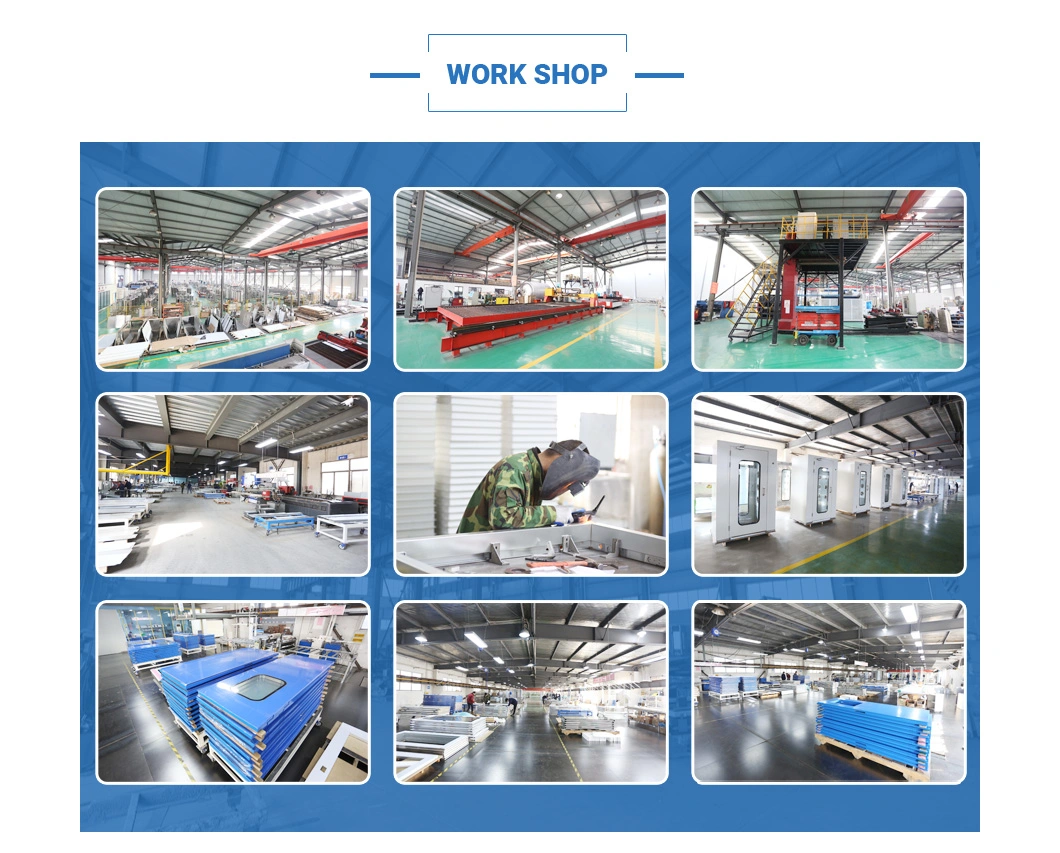

Workshop

Certificate

Project case

Our Customer

Exhibition & Our Team

Packaging & Shipping

Next: Rotary Tablet Press Machine Zpw17D with Factory Price High Quality Ce SGS Certificate for Sale

Our Contact