Marya China Pharmaceutical Vial Liquid Filling Sealing Production Line with Washing Stoppering Labeling

Description

Basic Info.

| Model NO. | MY-01 |

| Automatic Grade | Automatic |

| Material Type | Liquid |

| Filling Valve Head | Multi-Head |

| Feed Cylinder Structure | Multi-Room Feeding |

| Dosing Device | Capacity Cup |

| Filling Principle | Pressure |

| Packaging Container Lifting Structure | Pneumatic Lifting |

| Structure | Rotary |

| Packaging | Bottle |

| Packaging Material | Plastic |

| Color | Customized |

| Certificaate | ISO |

| Usage | Filling Machine |

| Function | Filling |

| Size | 200*100*100cm |

| Transport Package | Customized |

| Specification | Customized |

| Trademark | Marya |

| Origin | China |

| Production Capacity | 50000pieces/Year |

Packaging & Delivery

Package Size 100.00cm * 150.00cm * 100.00cm Package Gross Weight 100.000kgProduct Description

Marya China pharmaceutical vial liquid filling sealing production line with washing stoppering labeling

Product Description

Main Composition

The vial liquid filling line is composed of ultrasonic bottle washing machine, dryer sterilizer, vial filling stoppering machine, and vial capping machine. It can complete spraying water, ultrasonic cleaning, flushing of inner and outer wall of bottle, preheating, drying and sterilization, heat source removing, cooling, bottle unscrambling, (nitrogen pre-filling), filling, (nitrogen post-filling), stopper unscrambling, stopper pressing, cap unscrambling, capping and other complex functions, realizing automatic production of the whole process. Each machine can be used separately, or in linkage line. The whole line is mainly used for filling of vial liquid injections and freeze-dried powder injections in pharmaceutical factories, it can also be applied to production of antibiotics, bio-pharmaceuticals, chemical pharmaceuticals, blood products etc.

Performance Features

1.The aseptic vial filling line meets new GMP requirements, and the cleaning effect meets the new Pharmacopoeia standards and requirements.2.The whole injectable vial filling line can adopt straight-line layout or wall-to-wall L-shaped layout to reduce risk of cross-contamination and ensure aseptic level.3.Compact and simple structure, occupies less area;

4.Stable product performance, easy and reliable operation, beautiful appearance;

5.High degree of automation, few operators required;

6.Single row or double row filling;

7.Optional real-time display and printing system of sterilization temperature;

8.The heat in the hot air circulation tunnel oven is evenly distributed, and the heat resources removal effect is good.

9.Optional online sterilization function for the cooling section of hot air circulation tunnel oven.

10.Optional open-RABS isolation protection system and class 100 laminar flow hood protection;11.Optional high-performance no-bottle-no-filling, no bottle no stoppering, no bottle no capping and squeeze stop functions;

12.The capping machine can be equipped with dust exhaust device, which can absorb aluminum scraps produced during capping and thus reduce the risk of environmental pollution.

13.The whole line can be equipped with online monitoring system to monitor key factors that affect product quality (such as dust particles, planktonic bacteria, wind speed, wind pressure, etc.).

14.Full-line linkage control function;

15.To realize fully automatic control and monitor of production process, high precision colored touch screen operation monitoring, PLC automatic control and automatic protection, main machine frequency conversion speed regulation and other control technology are used.

16.Applicable for wide range of bottle specifications, and easy to replace mould.

17.The products can be customized according to customer's actual demand.

Technical Parameter

| Applicable Specification | 1ml-100ml vial (as per user's requirement) |

| Production Capacity | 1000-36000BPH |

| Number of Filling Head | 1-20, to be selected according to the output |

| Filling Accuracy | ≤ ±1% (according to drug characteristics) |

| Capping Qualified Rate | ≥99.9% |

| Filling Pumps | glass pump, metal pump, peristaltic pump, ceramic pump |

| Model | KGF4 | KGF6 | KGF8 | KGF10 | KGF12 | KGF20 |

| Applicable specifications | 2~30ml vial bottles | |||||

| Filling heads | 4 | 6 | 8 | 10 | 12 | 20 |

| Production capacity | 50-100bts/min | 80-150bts/min | 100-200bts/min | 150-300bts/min | 200-400bts/min | 250-500bts/min |

| Stoppling qualification rate | >=99% | |||||

| Laminar air cleanliness | 100 grade | |||||

| Vacuum pumping speed | 10m3/h | 30m3/h | 50m3/h | 60m3/h | 60m3/h | 100m3/h |

| Power consumption | 5kw | |||||

| Power supply | 380V 50Hz | |||||

Production procedures:

1.The compact line realizes single linkage, continuous operation from washing, sterilizing& drying,filling& stoppering, and capping. The whole production process realizes cleaning operation; protects products from contamination, meets the GMP production standard.2.The whole line adopts PLC total control, frequency converter, touch screen control technology, stable and reliable operation.3.Each machine has a power-off restart data saving function4.Ultrasonic washing CIP station for the mesh belt of sterilizer5.No vial no filling, no vial no stopper supply, no vial no capping6.Automatically reject for the unqualified vials7.Machine adopts superior SS 316L for part in product contact with product/drugs design to ensure cleaning and no dead angles 8.Industrial PC control with state of art features for Audit trail, data integrity, Graphical debugging and remote access

About Us

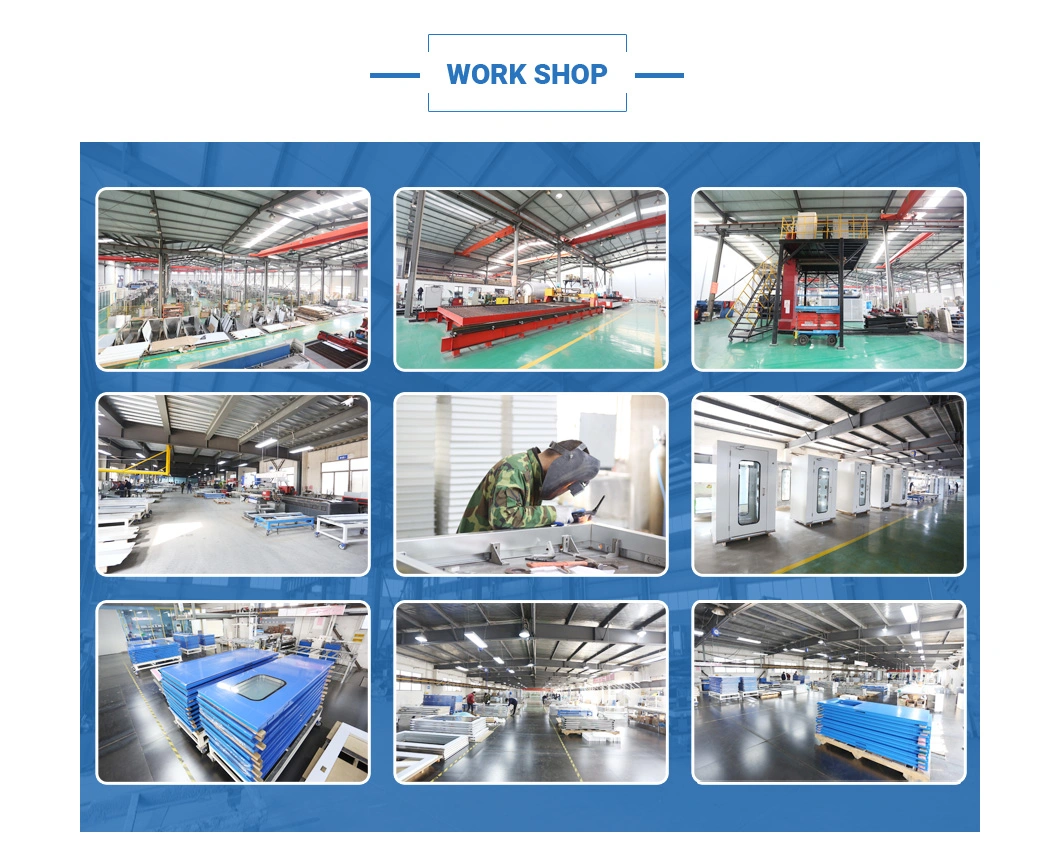

Workshop

Certificate

Project case

Our Customer

Exhibition & Our Team

Packaging & Shipping

vial liquid suspension filling machine

Our Contact