Shanghai Marya Pharmaceutical Pfs Machine Pre

Description

Basic Info.

| Certification | CE, GMP, ISO, SGS |

| Voltage | Customized |

| Computerized | Computerized |

| Customized | Customized |

| Condition | New |

| Warranty | 1 Year |

| Driven Type | Electric |

| Application | Phamaceutical Factory |

| Capacity | 2000-30000 Bph |

| Material | SS304 SUS316 |

| Filling Volume | 1-20 Ml |

| Machine Weight | 1500 Kg |

| Machine Size | 3500*1500*1800mm |

| Certificate | CE, ISO, SGS |

| Transport Package | Inner Water Proof Bag, Outer Sea Worth Case |

| Specification | customized |

| Trademark | Marya |

| Origin | China |

| Production Capacity | 30 Sets/Year |

Packaging & Delivery

Package Size 500.00cm * 128.00cm * 300.00cm Package Gross Weight 100.000kgProduct Description

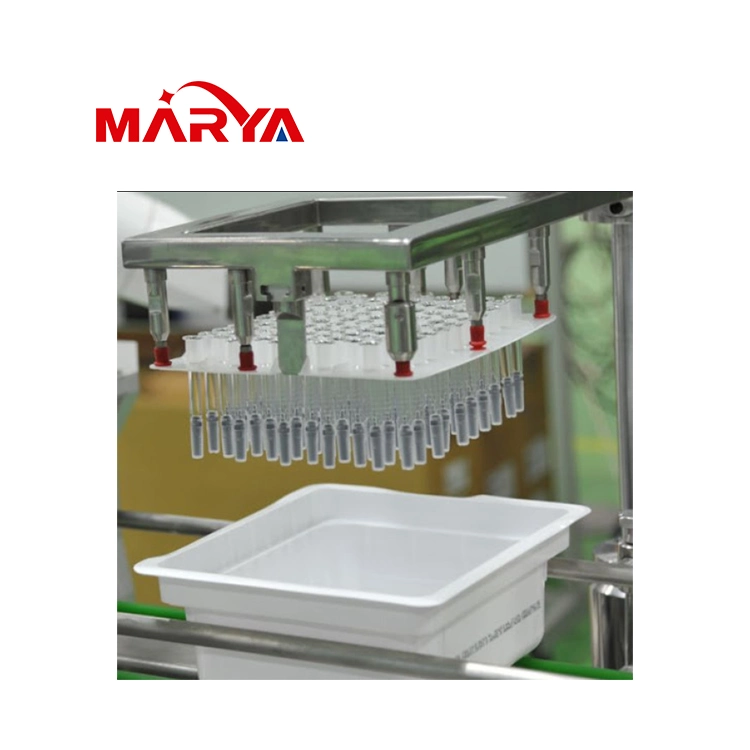

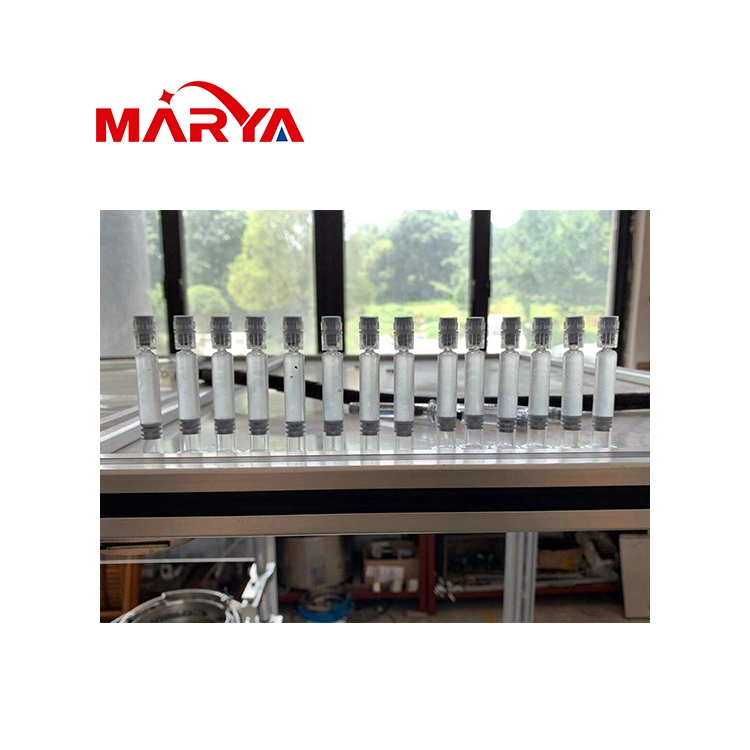

Shanghai Marya Pharmaceutical PFS machine Pre-filled Plastic Syringe Filling Stoppering Production LineMain ApplicationAseptic pre-filling and sealing syringe lines are mainly used for the unpacking, tearing, filling and pluging of disposable syringes in honeycomb trays in pharmaceutical plants. It's mainly for the production and packaging of various aseptic products such as vaccines, monoclonal antibodies, small molecule heparin, insulin and hyaluronic acid.

Performance Features

- The design, materials, manufacturing, assembly and commissioning of the entire line are in accordance with the new GMP and FDA regulations.

- This machine adopts servo control system to automatically complete the processes of honeycomb tray unpacking, tearing film, conveying, filling, plug feeding, plug filling and tray output. It's with electromechanical integration control, stable operation and high degree of automation.

- Applications: 1ml - 20ml (according to user specifications);

- Filling range: 0.1ml-20ml

- Capacity: 2000-30000 bph

- Filling head: 2-10 pcs, choose according to capacity;

- Various types of filling pump options: metal pump, peristaltic pump, ceramic pump;

- Filling accuracy: ≤ ± 1% (depending on the characteristics of the medicine).

- Pass rate ≥99.9%

- Automatic removal and return of the syringe from the honeycomb tray by means of a servo system combined with a cylinder;

- Fully automatic production control with intelligent testing devices at the core stations;

- No friction between the contact surface of the pluger and the drug solution and the bottom rail during transport. The stopper is always protected by laminar flow, avoiding the risk of particles and contamination;

- The main drive components of the machine are servo-driven and are located in the lower part of the machine frame, which allows precise positioning and avoids pollution of the environment;

- Can be equipped with a servo motor controlled filling pump for filling, which is highly accurate and easy to adjust;

- Configurable filling system CIP/SIP system;

- A nitrogen filling unit can be configured to isolate the medicinal solution from oxygen;

- Can be equipped with a vacuum filling system for filling the high viscous products;

- Configurable with Open-RABS isolation protection system and Class 100 air purification laminar flow system;

- The high-performance no bottle no filling, no bottle no capping and linked bottle squeeze stop function can be configured;

- Can be equipped with multiple robots for collaborative control technology to fully automate the process of tearing film, de-lining, filling, pluging and weighing of pre-filled syringes

- The automatic calibration of the filling volume can be configured to calibrate the filling volume fully automated;

- Can be equipped with fully closed aseptic isolation (Isolator) systems and bag-in-bag-out (BIBO) systems if needed;

- Fully automatic control and monitoring of the production process using control technologies such as high-precision colour touch screen operation and monitoring, PLC automatic control, automatic protection and mainframe variable frequency speed regulation;

- Can customized relevant products according to the actual needs of the customer.

Shanghai Marya Pharmaceutical Engineering&Project Co., Ltd is a professional Pharmaceutical Turnkey Project Contractor. We have 3 our own factories and more than 30 OEM factories under quality Control of Shanghai Marya, We have a 30 year experienced professional team for doing the turnkey project from design to construction.

Our Pharmaceutical projects can be done according to international standard like EU cGMP, USA FDA, WHO GMP, UK MHRA, Australian TGA, etc

We are not only a manufacturer but also a designing and construction company. We can provide much better price and better technical support and service than other companies

We can design and manufacture machines based on Customer's request, Your satisfaction is our top priority.

With 30 years of the experienced professional design team and construction team. Under the support of our factory, We can provide customer with high efficiency and quality in the project, save your time and cost.

Our machinery and projects have sold all over the country and they are exported to America, Europe, and the middle east, Southeast Asia, Africa, and other countries and regions.

Welcome to Visit Our factory in China

Packaging & Shipping

Standard export wooden case packaging.

Inner package: Stretching film

Delivery time:30-60 working days after receiving 30% deposit or L/C

Our Services

WHY US?

We can provide Pharmaceutical Turnkey project Service including all the pharmaceutical machinery and clean room projects from designing to construction

We can provide our project according to the international regulations like EU cGMP, USA FDA, WHO GMP, UK MHRA, Australian TGA, etc

We can provide 30-year experience engineer team go give you free Consultation service We Can provide FAT and SAT Service

We can provide DQ, IQ, PQ, OQ documents service

We can provide overseas machine installation and commissioning

We can provide free training service for your employee

We can provide One year guarantee for the machine and project

We can provide 24 hours of technical support by email

We can provide our installation team to your country to do the installation

We can provide user friendly English Software, user manual, and detailed video

You have nothing to worry if you cooperate with us for the pharmaceutical Project

Looking forward to cooperating with you.

Online contacts

Please contact us online for more details

Tel: +8618402158395

We are waiting for you online for 24 hours

Our Contact